1. Start with a good thinking is very important for the final result, roughly mark the position of those holes by compare to the template

2. Use the sandbag and Bossing Mallet to create those holes one by one, because the sandbag can be adjusted, so adjust it in a good shape to support the metal sheet, then use the Bossing Mallet hardly hit the marks on your metal!

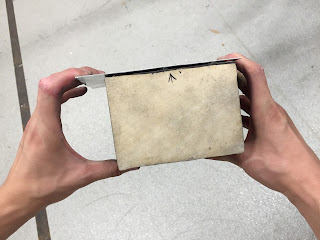

3. Compare to the template to see whether you are in a right direction or not. Here you can see that there is a big gap between the metal and template, that is because the head of the Bossing Mallet is not very sharp and the ductility of the metal cause the peripheral of the center bending as well

4. Find a flat surface and overturn the metal, use the Barrel Mallet showed above to hit the peripheral towards the center in order to narrow the hole. Keep doing this, then the gap between will become smaller than previous.

AFTER

5. However, the depth of the hole is not perfectly match the template. Hold the metal in the position against the tapered T-Dolly showed above, then hit the metal to refine the depth

No comments:

Post a Comment